We are Keyland Polymer UV Resins

The performance of an industrial UV-curable coating starts with quality resin: Faster, greener, and more profitable

Backed by over 20 years of success, Keyland Polymer delivers UV-curable resins and coatings that:

Increase production speeds by 3X-10X, use >50% less energy, and produce more profits. All with zero water or solvents.

Who we are

Keyland Polymer UV Resins is part of Keyland Polymer UV Material Sciences. Keyland UV Resins was founded in response to the growing demand for UV-curable powder coatings and other UV-curable materials in the European market and globally.

Located in Barcelona, Keyland’s resin synthesis lab develops resins for UV and EB-cured materials, supporting the transition to faster, more sustainable coating technologies.

Innovation and finding solutions are at the company’s core of work; we welcome new challenges and collaborate closely with our customers to develop custom resin solutions for industrial coatings and UV-curable applications.

With a fully equipped resin synthesis and powder coating manufacturing lab capable of producing small-batch samples up to 10 kg to support any project globally, we deliver results.

I want to learn more about Keyland Polymer’s Resins and Powder Coatings

What is in a UV-Curable Powder Coating?

Resin

Providing almost all the performance properties in the formulated coating, consisting between 60%-95% of the final coating formulation by weight.

Pigments, Additives, Fillers

Providing texture, aesthetic, and performance improvements for the coating.

Photoinitiators

Chemical compounds that absorb UV light and produce reactive species such as free radicals or ions, which trigger an instantaneous chemical reaction, curing the coating.

UV-curable powder coatings are produced on the same powder coating manufacturing equipment as thermoset powder coatings.

UV-Curable powder coatings offer:

- Instant Curing

- Superior Durability

- Maximum Efficiency

Keyland Polymer’s UV-curable solid resins and powder coatings are the innovation industrial finishing, using no water or solvents, and curing instantaneously when exposed to high-intensity UV light. These coatings are faster, more energy efficient, and eco-friendly.

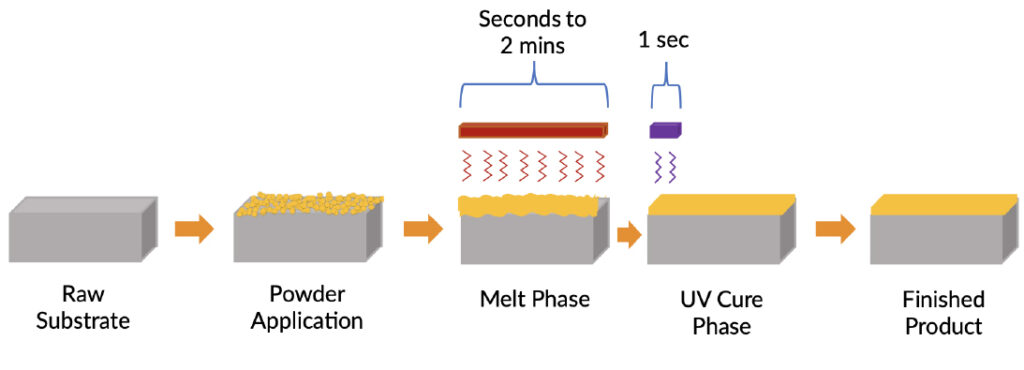

UV Powder Coating Process Steps

Powder application

The coating is evenly applied to the surface using the same technology for all powder coatings (electrostatic, fluidized bed, or scattering application process).

1

Melt phase

The powder melts at a controlled low temperature in seconds or 1 to 2 minutes* using IR, convection, induction, laser, or a combination of these heating technologies.

*depending on the energy source, powder formulation, and/or substrate*

2

UV curing

Ultraviolet light cures the coating instantly.

3

Finished product

The result is a high-quality coating processed in less time using less energy.

4

Suitable materials for UV-Curable Powder Coatings

Organic materials

- Solid Wood

- Plywood

- Medium-density fiberboard (MDF)

Metals

- Aluminum

- Pretreated Steel

Plastics / Composites

- Polycarbonate (PC) & PC/ABS

- PA-12 & PA-11 (Polyamides)

- Fiberglass

- Carbon Fiber

- Additive manufactured components

A faster and more sustainable UV-curable coating for applicators

New market opportunities for manufacturers through wood, plastic, and heat-sensitive material applications.

Finishing production in 4 hours instead of 4 days

3.5x – 10x faster production speeds

- Using less energy

- Smaller and more efficient systems

- Generates more profits

- Using no water or solvents